Deviating from theoretically exact dimensions often impair the function of the part. We suggest you read this article on.

External sizes, internal sizes, step sizes, diameters, radii, distances, external radii and chamfer heights for broken edges).

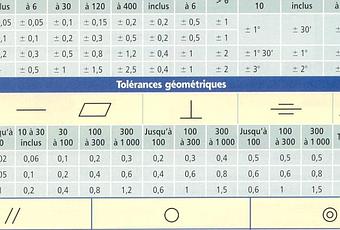

Norme iso 2768 mk. A guide to tolerance standards for cnc machining. Tolerance class is defined as per design requirements and manufacturing capability. Permissible deviations in mm for ranges in nominal lengths 0.5 up to 3 over 3 up to 6 over 6 up to 30 over 30 up to 120 over 120 up to 400.

General tolerances for linear and angular dimensions (din iso 2768 t1) linear dimensions: A round solid bar of 100mm length with ø50mm that will fit inside of a hole in another component. Every feature on a component always has a geometrical shape and size.

We suggest you read this article on. External sizes, internal sizes, step sizes, diameters, radii, distances, external radii and chamfer heights for broken edges). This part of iso 2768 only applies for the following dimensions which do not have an individual tolerance indication:

Geometric tolerance such as straightness, flatness, perpendicularity, symmetry, and runout. General tolerance november 2021 0. Iso2768 applies to dimensions which do not have an individual tolerance indication like linear dimensions (e.g.

General tolerances to din iso 2768.the latest din standard sheet version applies to all parts made to din standards.variations on dimensions without tolerance values are according to �din iso. Iso 2768 standard defines general tolerance for: Why iso 2768 is important.

Mark this document as not useful. Iso 2768 mk, iso 2768 1, iso 2768 2 created date: (din iso 2768 t2) straightness and flatness ranges in nominal tolerance class lengths in mm h k l up to 10 0.02 0.05 0.1

General tolerances to din iso 2768. External sizes, internal sizes, step sizes, diameters, radii, distances, external radii and chamfer heights for broken edges); General tolerance iso 2768 does not specify where to use these tolerances.

The latest din standard sheet version applies to all parts made to din standards. 1989, general tolerances — part 2: Therefore engineers define general tolerances in engineering drawings to define the variation.

Deviating from theoretically exact dimensions often impair the function of the part. You are on page 1 of 3. External radius and chamfer height.

General tolerances for linear and angular dimensions (din iso 2768 t1). The �m� specifies a medium tolerance range. Wildfires are dangerous, hard to control, and economically.